Trade study – a game everybody wants to play, but few know the rules. In the engineering world, “trade study” seems to be the epitome of systems engineering success. But in real-life Model-based Systems Engineering (MBSE) practices, what is a practical application of a tool like GENESYS for a trade study?

I will not claim to be an expert in performing a trade study, nor will I claim my method to be the only way to do it. As the title of the article suggests, this is merely one variation among many others you can leverage to accomplish a simple trade study. One might even say that this variant approach is a kind of the baseline “trade study”.

We will examine the following topics along the way.

- What GENESYS (and MBSE) can contribute to a trade study and what it cannot.

- The concept of inheritance with kind of and generalization of in the physical architecture.

- The concept of threads (or a variation of) with reflects and reflected in in the behavioral architecture.

- The use of Parameters and Parametric Diagrams in high-level performance trades.

An example we will be using for the trade study involves a simplified sport motorcycle design. Being an avid follower of Grand Prix Motorcycle Racing (MotoGP), I have always been fascinated by the complexity of the designs and setups of those powerful two-wheel racing machines. All of the bikes look very different on the starting grid in term of their color schemes, shapes, sponsorship decals, etc. However, their component settings and the resulting inherent performance are actually the greatest distinguisher between one bike and another. Some are good at providing raw power and acceleration. Some have the best handling capability in corners. Some manage tire-life very well, especially with a lighter fuel-load. And the alien-looking riders who tame these expensive mechanical beasts are all unique, with skills and strategy of their own.

For years, Repsol Honda has developed a title-winning package for Marc Marquez. But many other Honda riders considered the bike “un-rideable”. Surely, the ingenious engineers at Honda have done many trade studies to arrive at a design to fit both Marquez’s riding style and strategy. What if we attempt such a process in GENESYS for a particular aspect of racing: how to be the fastest in riding through a turn?

In recent years, there are two main types of motorcycle designs on the MotoGP grid: point-and-shoot and corner-speed. Ducati (and somewhat Honda nowadays) bikes are the point-and-shoot type. Their engines can generate a lot of power and torque. They can hit top speed very fast in a straight line, just before a turn. The bikes can brake very late into the corner entrance. Despite losing a lot of speed and momentum in the middle of the turn, they can swing around the corner in a sharper, more squared off radius. Then the bikes accelerate very quickly out of the corner, and achieve top speed quickly again.

Yamaha and Suzuki bikes are the corner-speed type. Their engines do not generate as much power; the riders do not brake as hard or as late. The bikes enter the corner with a lot of speed and momentum. The chassis designs allow the tires to hook up nicely with the track surface and carry the bikes around the turn with high speed and in a more shallow but tidy racing line. The bikes then do not need to accelerate as hard out of the corner since they are still traveling with more significant momentum.

As with everything else in life, you cannot have all the advantages without any disadvantages. If you are a new manufacturer coming to the GP grid, what kind of motorcycle design are you going to go with? A design trade study seems to be a logical starting point.

What is the role of MBSE and GENESYS in such a trade study? It might be a disappointment to a lot of engineers to learn that MBSE alone, regardless of the use of GENESYS, is not the only engineering discipline required to execute a trade study. What MBSE does, and GENESYS does very well, is to provide a descriptive architecture model of the system: what a system is, what a system does, and how to verify the system. There are a whole lot of analytical models needed to ensure a comprehensive and successful trade study: fluid-dynamic, aerodynamic, CAD, and mathematical. MBSE and GENESYS do not generate or execute these models. They can only act as the descriptive manager of trades and information exchanges between different design options. There is also a light-weight capability to examine a design’s mathematical behavior through parameters and the parametric diagram, which we will touch on in this example. At the end of the day, GENESYS can greatly add to your repertoire of tools to tackle a trade study, but never to replace your entire engineering toolbox.

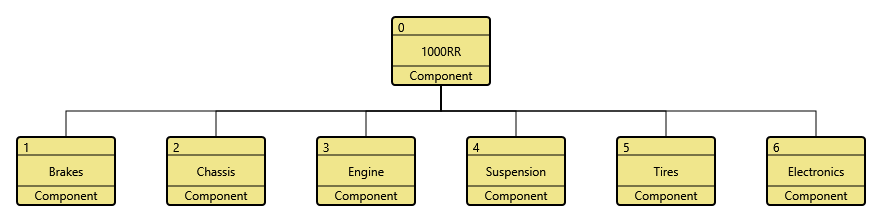

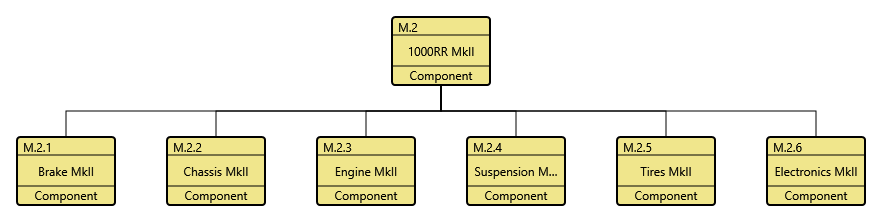

Now, onto what GENESYS can do very well in a trade study: setting a baselined physical configuration and creating traceability to different variants of the design. We can accomplish this by first decomposing the motorcycle (the 1000RR in this example) into its parts.

All physical-architecture best practices should be followed in building the baseline to make sure our design is well documented and specified. This is the step where we can leverage available parts “off the shelf”, empirically tested and proven parts, and integrable parts. It means, even without an actual assembled motorcycle, we can positively conclude that this baselined design would work, with predictable behavior and predictable performance.

From the baselined architecture, we will make a trade study on 2 sets of physical parts.

In a point-and-shoot bike, the chassis design is more rigid than that of a corner-speed bike. The frame and its subcomponents are built in a way to resist longitudinal deformation and lateral flexing under hard deceleration and acceleration. This design characteristic allows the point-and-shoot bike to stay more stable under hard braking into a turn and hard acceleration out of it. The rigid chassis design is then paired with a high-output engine to extract the most horsepower for the back-straight before and after a turn. The powerband control for mid-corner maneuver is not as important because this part of the turn is kept to a minimum in terms of the distance traveled.

In a corner-speed bike, the chassis design is more flexible than that of a point-and-shoot bike. The frame and its subcomponents are built in a way to allow longitudinal compression and lateral flexing under high-speed cornering. This design characteristic allows the corner-speed bike to “hug” the turn more efficiently, promoting better grip for the bike in mid-corner. As a result, more speed is possible during the turn. The flexible chassis design is paired with a lower-output engine but with smoother powerband control for mid-corner power delivery. The horsepower shootout in a back-straight with a point-and-shoot bike would be a sure defeat, however.

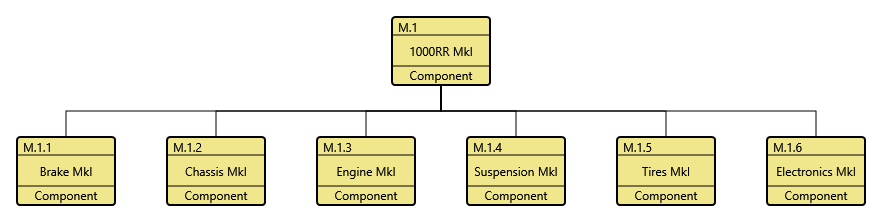

So out of the 6 typical components in the motorcycle design, we will focus on the chassis and engine tradeoffs. We will build 2 additional physical decompositions similar to the baseline, one for each bike design. The 1000RR MkI is the point-and-shoot design. The 1000 MkII is the corner-speed design.

We will set the relationship: “Chassis” (baseline) is generalization of “Chassis MkI” (point-and-shoot) and “Chassis MkII” (corner-speed). And, “Engine” (baseline) is generalization of “Engine MkI” (point-and-shoot) and “Engine MkII” (corner-speed). Now, we have the traceability from our baselined components to the components involved in the trade study. Any design decision down the road will be well informed and defensible against the predictable and well understood baseline design and performance.

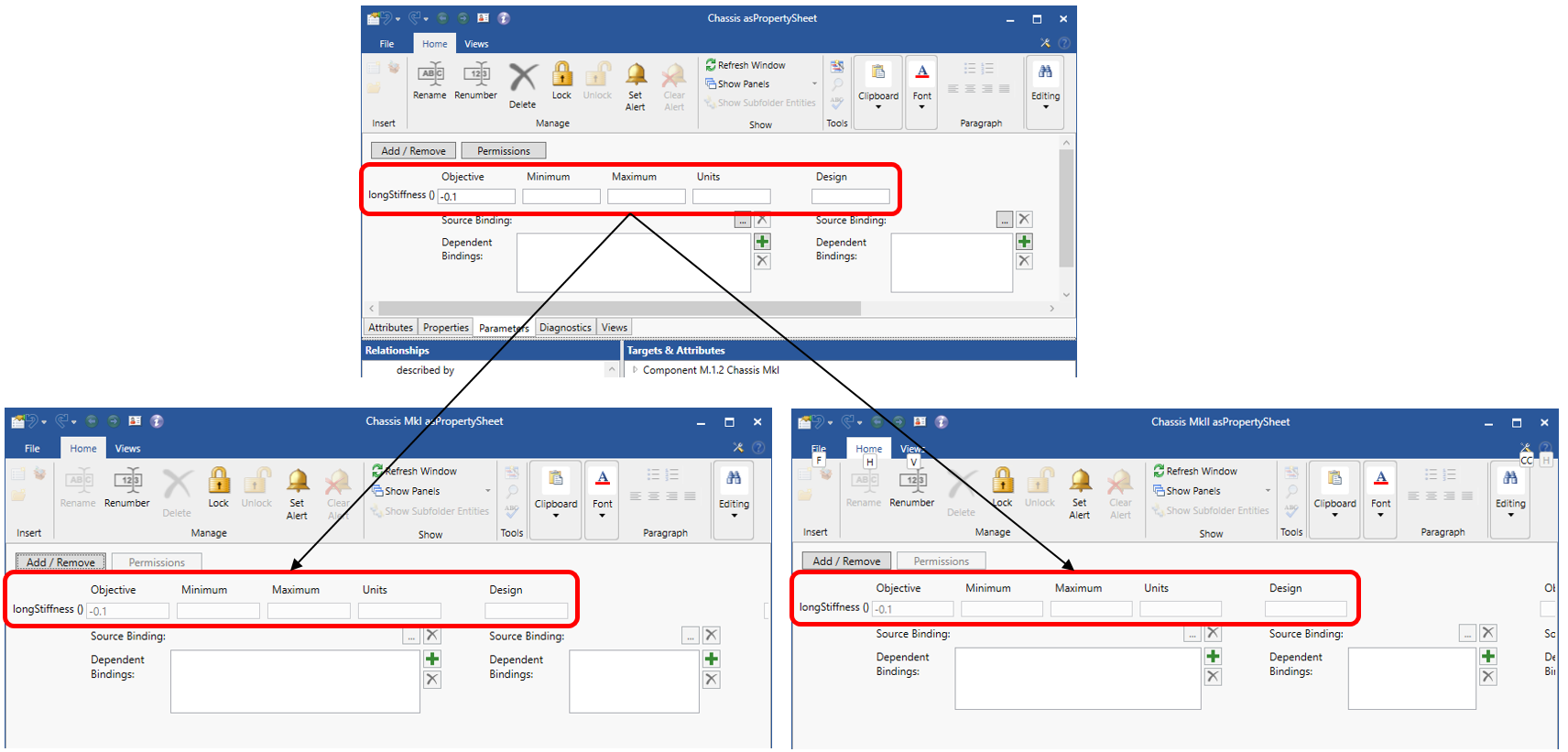

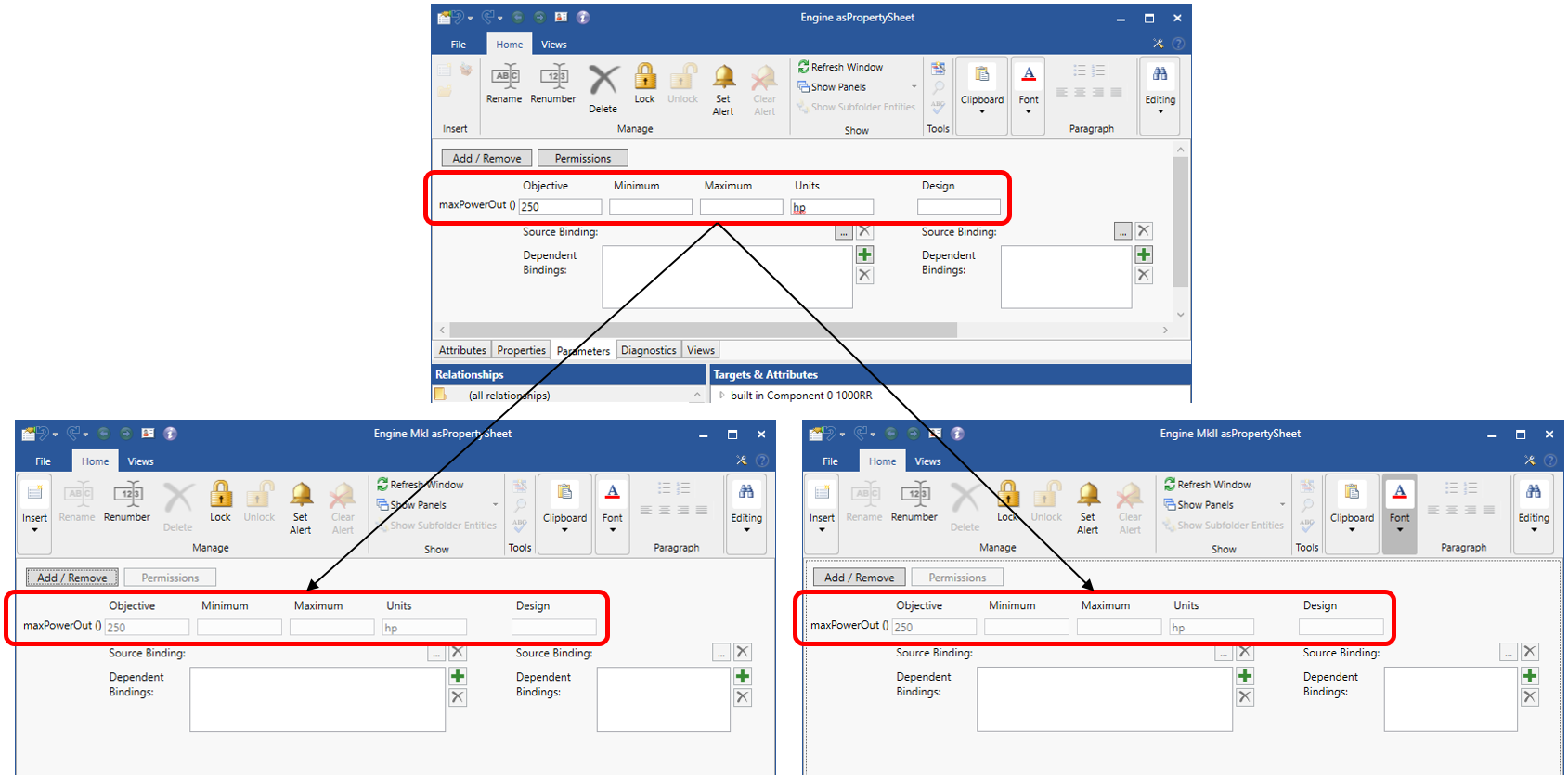

The relationship generalization of also provides the concept of inheritance. With inheritance, the same parameter used in the baselined component design is also inherited by the components involved in the trade study. In this example, the MkI chassis and MkII chassis inherit the “longitudinal stiffness” from the baselined chassis. (I created this parameter for the chassis design to be able to evaluate the components in the trade study quantitatively. I am neither a mechanical engineer nor a motorcycle designer. “Longitudinal stiffness” is merely fictitious characteristic invoked to demonstrate the relevant concept.)

This way, whatever mathematical expressions and parameters that we know as having worked well to evaluate the baseline (from historical usage), will also work well to evaluate the two design options fairly and consistently. We will also have the parameter “max power output” (fictitiously created for the baselined Engine) inherited by the MkI Engine and MkII Engine.

Having demonstrated the origin of these two parameters in the baselined design, we will address the use of these parameters in the next part of this article.

[To be continued…]