In a recent blog post “The Future of Fully Connected MBSE” and a webinar “Connecting GENESYS to Analytical Engineering Tools” I discussed the mechanisms available for GENESYS to support the analytical aspects of our engineering design activities. In this blog post I will outline an example of how GENESYS can support the analytical needs of a design. There are many mechanism available to support this, but for simplicity we will leverage the Microsoft Excel Connector to pull data from GENESYS, perform calculations, and push the results back to GENESYS.

It is vitally important that the data used by discipline engineers, as they make their decisions about the system solution, comes from a common source. The logical choice is for the data to come directly from the centralized model. The discipline engineers need the data in a structured form that is applicable for their analysis. They also need data that is meaningful for the analysis they are performing. The goal is to move from just model-based systems engineering to digital engineering.

Ideally we would like to achieve a situation where both the systems engineers and the discipline engineers can perform analysis and undertake design concurrently using a common pool of data and information. So as the systems engineers alter their aspects of the system’s design, the discipline engineers’ analyses immediately reflect the changes instigated by the systems engineers and vice versa.

GENESYS provides embedded analysis capabilities through its simulator which allows the behavior of the system to be analyzed using an event-driven simulation. But without custom scripting or other extension, we are unable to do analysis that involves solving equations within GENESYS. For example, we could not do any electrical voltage analysis as we look at size, weight, and power – and cost (SWAP-C) data within our model. So while the systems engineering model holds data that will be used by the discipline engineers, the models, by themselves, do not provide the necessary means of using that data in a manner that is relevant for the discipline engineers.

We can couple Excel with GENESYS to support a broad range of engineering analyses, both simple and complex. Certainly, there are other possibilities as well – Matlab, dedicated engineering packages, and custom code – but for the sake of illustration we will look at a classic engineering optimization problem regarding the number of piers in a bridge design. The optimization is based on the weight of the superstructure and the resultant total cost of the bridge. (This example is based on the example in “Systems Engineering and Analysis” by Blanchard & Fabrycky.)

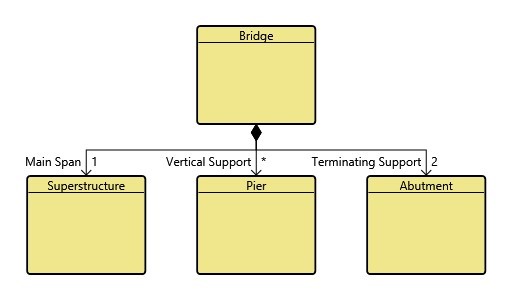

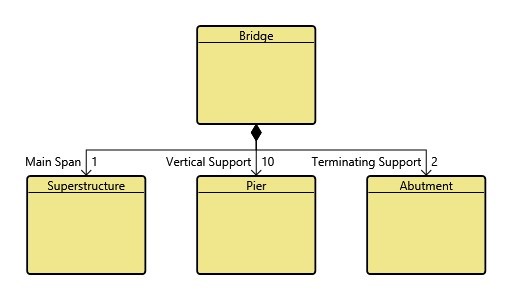

The systems engineer uses GENESYS to capture the major elements and their relationships in the bridge design: superstructure, piers, and abutments.

Structure Block Definition Diagram of the Bridge, Prior to Analysis

GENESYS parameters are used within the various Component entities to hold data values and data units associated with the design. The table shows the values that are known prior to the analytic engineering calculations.

| Parameter / Attribute | Bridge | Superstructure | Pier | Abutment |

| partMultiplicity | Known | Unknown | Known | |

| Length | Known | |||

| Span | Unknown | |||

| Weight | Unknown | |||

| Cost | Unknown | Known | Known | |

| Total Cost | Unknown | Unknown | Unknown | Unknown |

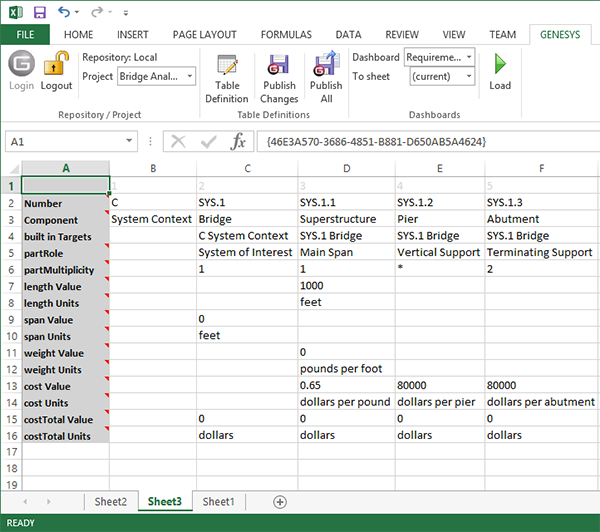

Once the design has been completed to a sufficient level of detail, the discipline engineer can use the Excel Connector to pull the model’s data out of the GENESYS repository to be used in the optimization calculations. In doing so, the design engineer does not need to be familiar with GENESYS. Instead, the design engineer works solely within an environment with which they are intimated familiar.

Model Parameters & Attributes Pulled into Excel

[Note: spreadsheet transposed for display]

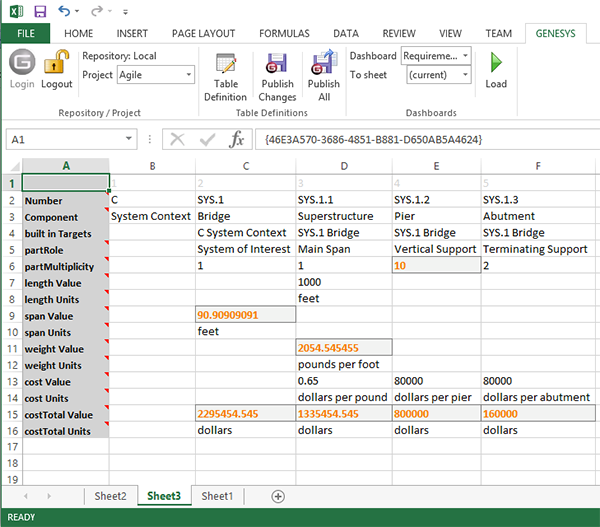

Once the data is in Excel the calculations necessary for the optimization can be made using the data. The resultant values can be written into the cells representing the unknown Component parameters and relationship attributes. (The formulas for the calculations can be placed in the cells that need their values calculated.) The values in the changed cells in the spreadsheet can then be published into the repository to update the model data.

Model Parameters & Attributes after Optimization Calculations in Excel

[Note: spreadsheet transposed for display]

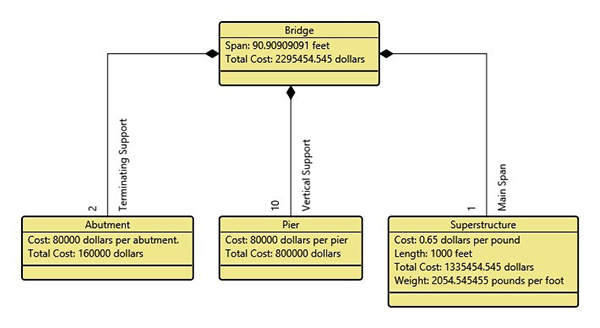

Once the new data is in the model, GENESYS immediately updates any views that use that data.

Structure Block Definition Diagram of the Bridge, after Optimization

Class Diagram of the Bridge, after Optimization

There are many other scenarios that connect the descriptive systems engineering design space served by GENESYS with the analytical engineering space served by a wide range of common and specialty tools. GENESYS provides a common source for the data used and produced by the systems engineers and discipline engineers. GENESYS delivers the data in a structured form both internally and to external applications. The net result is the systems engineer and discipline engineer are able to work concurrently on the model.

GENESYS provides value to the analytic engineering team, allowing them to have visibility of the model and its data as the systems engineers develop the design. The analytical engineering team is able to access the model data directly. They can then include their input into the design and the model via their own tools as and when appropriate bringing together the architecture and analytics necessary to successfully deliver systems.